ECOLOGY AND ENVIRONMENT

Environmental sustainability indicates the protection of the ecosystem and the preservation of the natural capital, by using responsibly the available resources. The following are the main projects developed by the researchers of the University in terms of ecological and environmental sustainability:

Innovative Micro solar Heat and Power System for Domestic and Small Business Residential Buildings (Innova MicroSolar)

The objective of the project is that of developing an innovative micro-cogeneration renewable energy system for domestic application. Electricity is produced using a 2kWe/18kWt ORC unit which riceives heat at 250 °C thanks to a concentration solar power installation based on Fresnel linear reflector. Furthermore, the power generation plant, is equipped with a heath storage system realized with phase change material for the purpose of granting the production of thermal and electrical energy even in absence of solar radiation, for a period of 3-4 hours.Finally, an intelligent control system enabling the management of the integrated systems and its interaction with the users. The installation thus realized is currently being tested in Almatret (Spain) with the aim to provide around 60 per cent of the energy required by a household, with the ultimate goal of contributing to the decarbonisation of the residential sector of about 250°C thanks to a concentration solar power installation based on Fresnel linear reflectors.

Enhancement of engineering skills of students of all levels for application of evidence based sustainable renewable energy solutions in the built environment (Skybelt) Erasmus+ Key Action 2: Capacity Building in Higher Education

The aim of the project is to improve the knowledge and abilities of the students (at all levels) of the universities involved in the field of technologies for renewable sources that can be integrated. Essentially, said objective should be pursued through three separate actions: (i) modernisation of the modules related to the scope of the projecr at Asian universities including distance learning modalities and new laboratory equipment; (ii)incentivization of internship and mobility activities by students; (iii) involvement of companies working in these areas in order to create a network of skills and knowledge that can continue after the end of the project.The project started at the end of 2019 and will last 3 years. Project reference number: 610258-EPP-1-2019-1-EN-EPPKA2-CBHE-JP

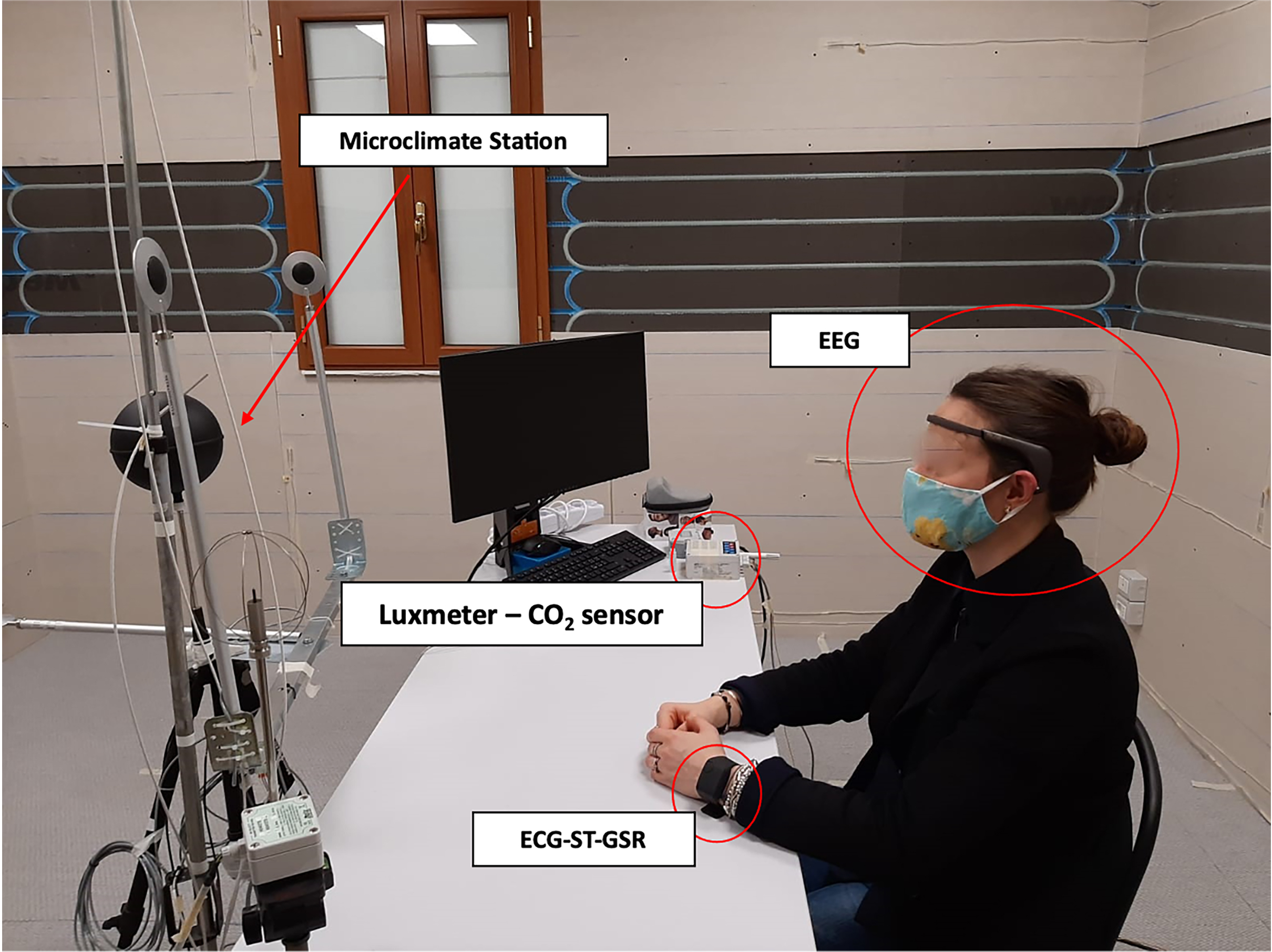

NEXT.COM – The NEXT generation of multiphysics and multidomain environmental COMfort models: theory elaboration and validation experiment PRIN2017 – MIUR

The purpose of the project is to develop a new methodology for analysing environmental comfort through a multi-physics, multi-domain and multi-sensory measurement and modelling protocol. NEXT.COM aims to answer the need to interpret with great accuracy the factors influencing people's behaviour inside buildings, which, in turn are the base of energy consumption. To this end, the project will exploit the potential of new technologies in terms of measuring physiological and environmental quantities (e.g. skin temperature, galvanic response, brain and heart activity, IoT environmental sensors, virtual reality). The acquired data will be analysed with typical Machine Learning methodologies for the development of new comfort predictive models that can be integrated into dynamic models for building energy simulation.

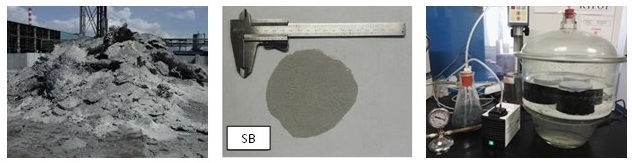

Study on the Possibility of Employment of the Filler Product with "White" Ladle Furnace Slag in the Production of Bituminous Conglomerate.

The aim of the present research is to evaluate the possibility of employment of the Filler Product with "white" ladle furnace slag, deriving from the Pittini production plants, as fillers in the production of bituminous conglomerate. The objectives of the study were: – to assess the physical properties of the ladle slag in order to verify the possibility of its reuse in asphalt mixes; – to define an appropriate procedure for processing the ladle slag in order to obtain asphalt mixes with physical-mechanical characteristics comparable to those of mixtures produced with industrial hydrated lime fillers; – the laboratory validation, in terms of volumetric and mechanical properties, of the asphalt mix containing ladle slag filler, compared with a traditional mix made from recovered limestone filler. The project took place between march and september 2017.

Mitigating The Risk Of Flooding And Landslides Via Artificial Intelligence With A View To Extreme Climate Events (SAFE-LAND)

The project proposes a system that combines analytical/numerical methods with reliable AI techniques

for landslide and flood risk assessment and the generation of guidelines on risk management planning

and on increasing risk awareness in the population, even when hydrogeological/demographic data are

incomplete. The system is based on a knowledge database consisting of reference areas and reference

climate events. Reliable AI makes the tool unique because it explains how the results are achieved,

making its reasoning understandable and reliable. Experts can use the system to plan mitigation

interventions and insert new reference areas/climate events into the knowledge base, thus obtaining

a lifelong learning tool. The project involves Italy, Croatia and Montenegro, which will collaborate

and provide data regarding the areas where the pilot studies will be carried out.

The project started in February 2024 and will last 2 years.

MULTIDIMENSIONAL SEISMIC RISK ASSESSMENT COMBINING STRUCTURAL DAMAGES AND PSYCHOLOGICAL CONSEQUENCES USING EXPLAINABLE ARTIFICIAL INTELLIGENCE (MEDEA)

The project proposes a multidimensional system for seismic risk assessment in cross-border areas, whose dimensions are damage to infrastructure and psychological consequences for the individuals involved. The proposed system combines analytical/numerical calculation methods with Artificial Intelligence models to estimate damage to infrastructure following a seismic event, losses and psychological consequences for the individuals involved. The system will be available to the competent authorities and will help civil protection authorities in planning mitigation strategies to reduce damage and losses. The project involves Croatia, Italy and Slovenia and foresees the application of the proposed system in pilot cross-border areas between Italy-Slovenia and Slovenia-Croatia. The project started at the end of 2022 and will last 2 years.

Fostering Renewable energy technologies and energy Efficiency knowledge towards near Zero Energy Buildings of engineers and professionals in Western Balkan Countries (reZEB)

The project aims to improve the knowledge and skills of students of vocational and engineering

training courses of the institutions of the Balkan countries involved in the field of renewable

energy technologies and energy efficiency to make buildings nearly zero-energy. Within the project,

this objective is pursued essentially through: (i) the modernization of the modules relating to the

topics of the project at the Balkan universities including distance learning methods and new

laboratory equipment; (ii) the promotion of student internship activities; (iii) seminar activities

and short training courses aimed at both students and the business world in order to promote

lifelong learning and the requalification of workers' skills.

The project started at the end of 2023 and will last 3 years.

Project reference number: GA 101128611

WEPOP – WEarable Platform for OptImised Personal comfort

Personalized comfort approaches are considered among the most promising for the measurement and control of indoor thermal comfort. They exploit the integration of physiological, environmental and personal data to create personal comfort models (PCMs) useful for measuring thermal sensation with a higher degree of accuracy than current measurement methods based on generalized models. The PCMs thus generated, thanks to the diffusion of wearable devices and IoT sensor networks, can be used for the optimal management of air conditioning systems. Despite the progress made in the field of wearable devices, IoT and artificial intelligence (AI), the full potential of PCMs has yet to be demonstrated when taking into account the uncertainty of wearable sensors, environmental effects and physiological variability. The WEPOP project therefore aims to develop and validate a platform dedicated to the real-time measurement and control of personal comfort based on physiological and environmental sensors. WEPOP will develop measurement and data analysis systems and methods to reduce uncertainty and enable the application of Personal Comfort Models in real-world contexts. Furthermore, thanks to the integration with innovative Digital Twin systems for building management, WEPOP aims to improve the sustainability of buildings by ensuring better comfort but with a 10% reduction in energy consumption compared to traditional climate management systems.

SUPRA – Single Use PPE Reinforced Asphalts

The project, winner of the Call for funding research activities aimed at reducing waste produced by

single-use plastic - 2021 Edition - of the Ministry of Ecological Transition, has as its main

objective the research and validation of an innovative product based on the reuse of waste plastic

material deriving from the disposal process of personal protective equipment (PPE) used to prevent

the spread of the Covid-19 pandemic (masks and gloves). This fiber, appropriately treated and

processed, may find application in the creation of products to be used in the road infrastructure

sector, with the aim of proposing a circular economy scenario. The aim is to use waste textile

material, deriving from end-of-life PPE, for the production of bituminous conglomerates

characterized by better technical characteristics compared to standard non-reinforced conglomerates

The project was divided into the following sub-objectives:

• Study and research of the best recovery and reuse scenario of polymeric textile fiber

deriving from PPE used during the Covid-19 emergency;

• Study and research of the technical-economic feasibility of the application of waste

material from PPE as a reinforcing/improving agent for the characteristics of bituminous

conglomerates;

• Testing and validation of the prototype in several pre-industrial case studies.

Construction of experimental layers of hot bituminous mixes of base and binder type with high contents of recycled bituminous mix (milled)

Aeroporti di Roma S.p.A. has signed a Research Contract with CREAT with the aim of maximizing the

reuse of the milled material, evaluating the possibility of increasing its hot bituminous

conglomerate content and applying cold recycling technology, which allows the replacement of the

virgin aggregate with the milled material up to almost 100%.

For this purpose, in the months of January and February 2023 a pilot section was built

along the Bravo dell taxiway, where the following experimental mixtures were produced and installed:

• Binder in bituminous conglomerate with hard modified bitumen and 50% of recycled

bituminous conglomerate;

• Base in bituminous conglomerate with hard modified bitumen and 50% of recycled bituminous

conglomerate;

• Cold base made on site, containing 96% of recovered bituminous conglomerate stabilized with

modified bitumen emulsion and cement. Specifically, the hot bituminous conglomerates (binder and

base) with 50% of milled material were packaged using a particular hard modified bitumen with a high

content of aromatic fractions, specifically designed to allow the regeneration of the oxidized

bitumen present in the milled material.

Study on fatigue behavior and damage propagation in asphalt rubber type bituminous conglomerates

The experimental program involved the analysis of two different types of Asphalt Rubber bituminous

conglomerates, produced respectively with the dry Italia and wet methods.

The experimental study involved the following laboratory investigations:

– cyclic compression tests in the viscoelastic field, carried out at different temperatures

and wave frequencies, for the measurement of the complex Young's modulus (norm and phase angle)

– cyclic triaxial tests with compression load waves, for the measurement of the permanent

deformations accumulated by the specimens at high temperatures

– cyclic indirect tensile

fatigue tests, carried out at constant temperature and frequency with the application of different

horizontal stresses, for the construction of the fatigue curves

– indirect tensile breaking

tests with analysis of the breaking energy. The tests were carried out with the NAT (Nottingham

Asphalt Tester) equipment. This equipment, consisting of a servo-pneumatic press contained within a

climatic chamber for temperature control, allows the execution of uniaxial and triaxial dynamic

tests on bituminous conglomerate mixtures, in compliance with the EN 12697-24, EN 12697-25 and EN

12697-26 standards.

The project took place between May 2014 and November 2015.